¿Cómo Funciona?

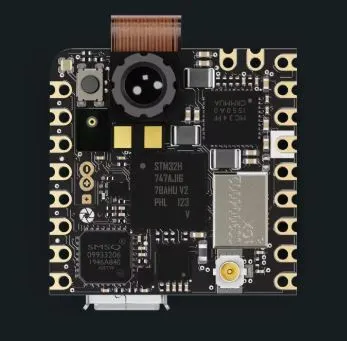

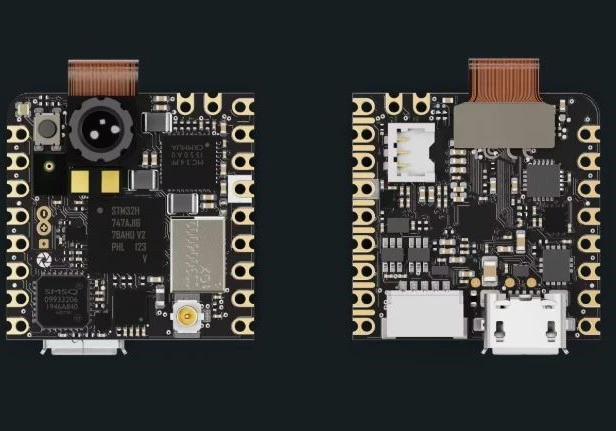

1. IoT Sensors

Nuestros sensores avanzados recopilan datos en tiempo real de vibraciones, temperatura, presión y otros parámetros críticos.

2. Camaras de video y micrófonos

Edgemant procesa flujos de audio y video en tiempo real en el borde, permitiendo la detección de eventos y reconocimiento de patrones sin depender de la nube.

3. Protocolos de campo

Edgemant esta entrenado en los protocolos de Campo usados en industria y esificios.OPC-UA,Mqtt,Modbus,Profibus

4. Manuales

La plataforma construye una base de conocimiento a partir de los datos, aprendiendo continuamente para ofrecer insights cada vez más precisos.

5. API's

Para obtener datos externos de aplicaciones como el clima, las noticias o información de reguladores, entre otros, que ayuden a tomar decisiones informadas.

6. Edge IA y Cloud

Procesamiento Edge IA para respuesta inmediata local, sincronizado con Cloud para análisis avanzados, detectando patrones y anomalías antes de las fallas.

6. CO.- Mantenimiento

Recibes alertas proactivas y recomendaciones específicas para optimizar el mantenimiento y evitar paradas no programadas.

7. CO- Operacion

El sistema puede tomar acciones correctivas de forma autónoma, ajustando parámetros para mantener la operación óptima y segura.

8. CO- Seguridad

Protege tus datos procesándolos localmente, sin exponer información sensible en la nube. Además, aplica cifrado y controles de acceso para mantener la operación segura